Reduced Bottle-Filling Machine Setup Time Waste Using Single-Minute Exchange of Die (SMED): A Case Study of a Fish Sauce Plant

Keywords:

Bottle Filling Machine Setup Time, Single-Minute Exchange of Die (SMED), Fish Sauce PlantAbstract

This study investigates the application of a Single-Minute Exchange of Die: SMED to reduce the setup time for the fish bottling-filling machine. The reduction of waste in bottle-filling setup time is a key aspect of enhancing work productivity while minimizing production downtime. The data was collected through a non-participant observation method, with video data recorded on the business's video recorder, in order to examine the manufacturing staff’s pre- and post-work processes in setting up the bottle-filling machine. The study's findings found that reducing the remaining activities for adjusting the bottling machine setup time from 13 to 9 reduced the average setup time from 237 minutes to 124 minutes, or a 47.68 percent decrease. The findings of this study can help guide operations for businesses in the bottling industry by reducing machine set-up time using SMED principles in order to increase production efficiency and minimize production costs through reduced time.

References

Borges Lopes R, Freitas F, Sousa I. Application of lean manufacturing tools in the food and beverage industries. Journal of Technology Management & Innovation. 2015;10(3):120 -30.

Dillon AP, Shingo S. A Revolution in Manufacturing: The SMED System: CRC Press; 1985.

Askin RG, Goldberg JB. Design and Analysis of Lean Production Systems: John Wiley and Sons; 2007.

Malindzakova M, Malindzak D, Garaj P. Implementation of the single minute exchange of dies method for reducing changeover time in a hygiene production company. International Journal of Industrial Engineering and Management 2021;12(4):243-52.

Ulutas B. An application of SMED methodology. International Journal of Industrial and Manufacturing Engineering 2011;5(7): 1194-7.

Sugarindra M, Ikhwan M, Suryoputro M. Single Minute Exchange of Dies as The Solution on Setup Processes Optimization by Decreasing Changeover Time, A Case Study in Automotive Part Industry. IOP Conference Series: Materials Science and Engineering 2019;598:Article No 012026.

Trovinger SC, Bohn RE. Setup time reduction for electronics assembly: Combining simple (SMED) and IT-based methods. Production and Operations Management 2005;14(2): 205-17.

Kusrini E, Parmasari AN. Productivity improvement for unit terminal container using lean supply chain management and single minute exchange of dies (SMED): A case study at Semarang Port in Indonesia. International Journal of Integrated Engineering 2020;12 (1):122-31.

Bonamigo A, Bernardes PMM, Conrado LF, Torres LF, Calado RD. Patient flow optimization: SMED adoption in emergency care units. IFAC-PapersOnLine 2022;55 (10):204-9.

Guzel D, Asiabi AS. Improvement setup time by using SMED and 5S (an application in SME). International Journal of Scientific and Technology Research 2020;9(1):3727-32.

Runtuk JK. Set up time reduction using single minute exchange of dies (SMED) and 5S: A case study. JIE Scientific Journal on Research and Application of Industrial System 2021;6(2):162-71.

McIntosh R, Owen G, Culley S, Mileham T. Changeover improvement: Reinterpreting shingo's “SMED” methodology. IEEE Transactions on Engineering Management 2007;54(1):98-111.

Mulla M, Bhatwadekar S, Pandit S. Implementation of lean manufacturing through the technique of single minute exchange or die (SMED) to reduce change over time. International Journal of Innovative Research in Science, Engineering and Technology 2014; 3(6):13069-76.

Cooper J, Lewis R, Urquhart C. Using participant or non-participant observation to explain information behavior. Information Research 2004;9(4):9-4.

Handley M, Bunn F, Lynch J, Goodman C. Using non-participant observation to uncover mechanisms: Insights from a realist evaluation. Evaluation 2020;26(3):380-93.

Palinkas LA, Horwitz SM, Green CA, Wisdom JP, Duan N, Hoagwood K. Purposeful sampling for qualitative data collection and analysis in mixed method implementation Research. Administration and Policy in Mental Health and Mental Health Services Research 2015;42(5):533-44.

Asan O, Montague E. Using video-based observation research methods in primary care health encounters to evaluate complex interactions. Informatics in Primary Care 2014;21(4):161-70.

Caldwell K, Atwal A. Non-participant observation: Using video tapes to collect data in nursing research. Nurse Researcher 2005;13(2):42-54.

Ciesielska M, Boström KW, Öhlander M. Observation methods. In Ciesielska M, Jemielniak D, editors. Qualitative Methodologies in Organization Studies: Volume II: Methods and Possibilities. Palgrave Macmillan; 2018. p. 33-52.

Hasabe A, Hakde A, Khandagle A, Surve K. Single minute exchange of dies (SMED) concept. International Research Journal of Eng Technol 2019;6(04):4665-9.

Athikulrat, A. A Standard Time Study of Install the Paint Mold: A Case Study of Magnetic Annex Supply Partnership. Journal of Engineering, RMUTT 2019; 17(1):77-90.

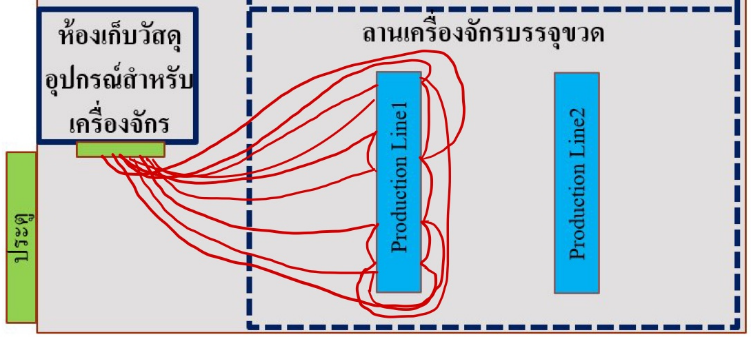

Pyzdek T. Spaghetti Diagrams. The Lean Healthcare Handbook: A Complete Guide to Creating Healthcare Workplaces: Springer; 2021:25-8.

Senderska K, Mareš A, Václav Š. Spaghetti Diagram application for workers’ movement analysis. UPB Scientific Bulletin, Series D: Mechanical Engineering 2017;79(1):139-50.

Benyathiar P, Kumar P, Carpenter G, Brace J, Mishra DK. Polyethylene terephthalate (PET) bottle-to-bottle recycling for the beverage industry: A review. Polymers 2022;14(12): 2366-95.

Lonca G, Lesage P, Majeau-Bettez G, Bernard S, Margni M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resources, Conservation and Recycling 2020;162:105013-23.

Athikulrat, A. Productivity improvement by fundamental of hand motions: A case study of assembly line in an electronics company. RMUTP Research Journal 2017;11(1):165-76.

Downloads

Published

Issue

Section

License

บทความทุกบทความที่ตีพิมพ์ในวารสารการพัฒนางานประจำสู่งานวิจัย (JPR2R) ถือว่าเป็นลิขสิทธิ์ของวารสารการพัฒนางานประจำสู่งานวิจัย คณะสิ่งแวดล้อมและทรัพยากรศาสตร์ มหาวิทยาลัยมหิดล